Dust Monitoring & Dust Management

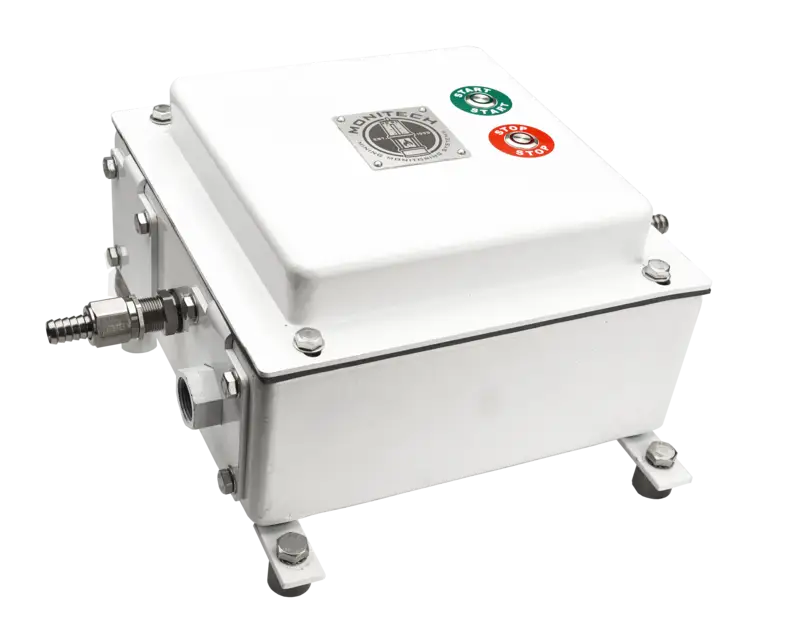

MONITECH MACHINE MOUNTED REALTIME DUST MONITOR (MRDM):

FUNCTIONALITY & PERFORMANCE:

- MRDM system enables Management, Miners and Operators to monitor the dust generated in all areas where monitoring dust generation is required.

- MRDM provides real-time environmental reporting while also offering connection to a remote monitoring interface:

- The MRDM provides real-time dust monitoring up to 30mg/m³.

- MRDM is available in I.S and Non-I,S variants for machine mounted and fixed (roadway) applications.

- Space saving compact MRDM enclosure allows for easier placements on machines.

- The MRDM is designed to be Intrinsically safe with a live I.S 4-20mA output.

- The MRDM is fitted with a 2.4” colour display for live readings, sensor status and diagnostics for the user.

- Output from MRDM to Smart dust Display – 4-20mA

- MRDM is linked to a Smart Dust Display that has configurable alarm (Green/Orange/Red) and trip levels for interlocking to the machine.

- Main display shows the current shift average:

- If the average exceeds 3mg/m3, the display colour will change to ORANGE.

- If the average exceeds 4mg/m3, the display colour will change to RED (flashing).

- If the average exceeds 5mg/m3, the display will be solid RED.

- Local manufacture and accessibility to product.

- Lower maintenance requirements.

SPECIFICATIONS:

- Max. relative humidity: <95% non-condensing

- Operating temperature: -10°C to +50°C

- Input Voltage: 21 – 25.2VDC

- Input Watts: <3W

CERTIFICATION:

- Certified in accordance with SANS 60079 – 11: 2012

- Ex ia I Ma I

- Number MASC M/22-8416X

DUST STOP SUPPRESSION SYSTEM:

Functionality & Performance:

- The Dust Stop Suppression System is an industry proven Whole Dust suppression system for both underground and surface working environments.

- Dust Stop uses an airless system to feed water through custom designed airless foaming nozzles that draws the foaming agent into the water supply,

- The additive when agitated increases the water volume by up to 7 times to improve the contact area, reducing water tension and increases the contact area to create a blanket effect attracting dust.

- The system forms part of a holistic dust suppression solution

- Easy to install, does not interfere with operations and requires very little maintenance.

- Additive composition is non-hazardous, with a 3-hour downstream effect that continues to suppress dust.

- Dust Stop systems requires no electrical or hydraulic power to operate.

- Installations are backed by the Monitech 24/7/365 service offering if required.

- Each Dust Suppression solution is custom fitted specific to each customer’s requirements

APPLICATION POINTS:

- Surface and Underground Application points

- Continuous Miners

- Feeder Breakers

- Belt Transfer Points

- Bunkers

- Stockpiles

CERTIFICATION:

- I.S. Compliant

- S.A.C.A.S ISO 9001:2015

- Additive Safety Data Sheet available on request

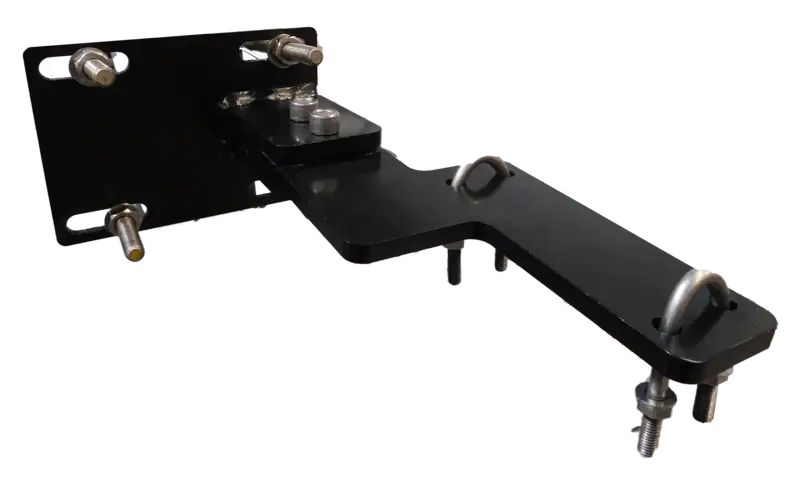

MONITECH INTELLIGENT WATER MANAGEMENT SYSTEM:

Functionality & Performance:

- The Monitech Intelligent Water Management System is a highly cost effective, Whole Dust suppression system for both underground and surface working environments.

- Modular system using intelligent automated systems with no mechanical contact

- The intelligent water management system optimises operational water, using an optimal configuration of Actuator Ball valves, Solenoids, Sensors and custom designed water spray pipes and custom nozzles.

- The system both optimises operational water utilisation, with savings of up to 75%, and assists in suppressing dust.

- The system forms part of a holistic dust suppression solution that is even more effective when used in conjunction with the Dust Stop system.

- Easy to install, does not interfere with operations, equipped with reverse flushing technology that requires very little maintenance.

- Water management systems requires no electrical or hydraulic power to operate.

- Installations are backed by the Monitech 24/7/365 service offering if required.

- Each water management solution is custom fitted specific to each customer’s requirements.

- Strong robust design

APPLICATION POINTS:

- Surface and Underground – In Bye and Out Bye Application points

- Feeder Breakers

- Belts – supplying water sprays on bottom belts where fine dust has accumulated.

-

Section Belt Systems

- Main Belts Systems

- Transfer Points

- Bunkers

- Stockpiles

CERTIFICATION:

- Certification for the different systems is available on request.

- I.S. and FLP configurations are available.