MSHA APPROVED EQUIPMENT

AMERICAN MINE SAFETY AND HEALTH ADMINISTRATION (MSHA)

Monitech designs equipment for use in hazardous areas using many different techniques based on customer specific applications, local regulations and standards. We have systems approved by the American Mine Safety and Health Administration (MSHA).

M5 is the next-generation system from Monitech and represents a significant improvement over existing methane monitors available in the US coal market. M5’s unique sensor design, system software and beacon sensor monitoring technology make it more precise and enable it to maintain a stable zero setting.

“Current methane monitors can be a hindrance to productivity either through system faults or inspection stoppages,” said David Clardy, President of Matrix Design Group. “M5 couples mine-tested technology with several new design features to help improve operational efficiency.”

The unit is highly water- and vibration-resistant, easy-to-calibrate and simple to maintain. Because users can calibrate the M5 on the display or beacon, a miner can apply test gas to the sensor and magnets to the beacon without going back to the display. And while miners still need to bump-check each shift, the 4-20 milliamps connection allows for a more stable calibration, so they generally don’t need to calibrate as often. Additionally, mines that are required to run two sensors per CM find that they only need to use one unit, since the M5 can monitor both sensors using a single controller/display and power supply. The M5 is RS485 and CAN-bus enabled, which will allow for the Methane Monitor Override Function if a system fault occurs in the face.

While M5 delivers a new monitoring technology to the US market, its maintenance is similar to currently available systems, allowing for easy adaptation for mine personnel. Matrix also has a highly experienced field service staff that are available to train and advise mines as well as install and service the M5.

MONITECH ROOFBOLTER LASER GUARD:

FUNCTIONALITY & PERFORMANCE:

- A laser system designed to be fitted to both single or dual boom Roof Bolting Equipment to assist machine operators avoid potentially hazardous situations while performing roof bolting functions

- The laser scanner is mounted in an established position on the machine and produces an invisible barrier directed in front of the drilling head of the roof bolter

- Once this laser path is broken by (hand, limb or obstacle) the laser recognises this and operates a relay which in turn switches off a solenoid which is used to stop the rotation of the drill head function

- Once the obstacle is removed from the path of the beam, the system automatically resets and the drill rotate function resumes

- A complete Laser Guard System includes:

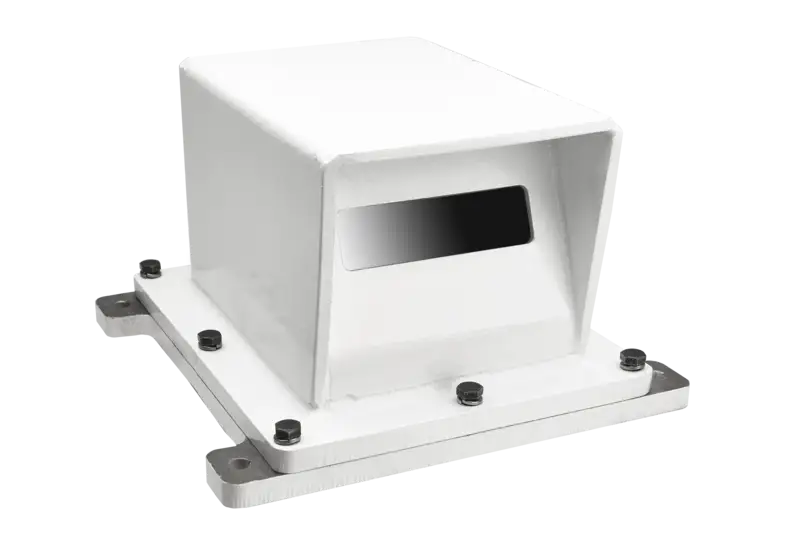

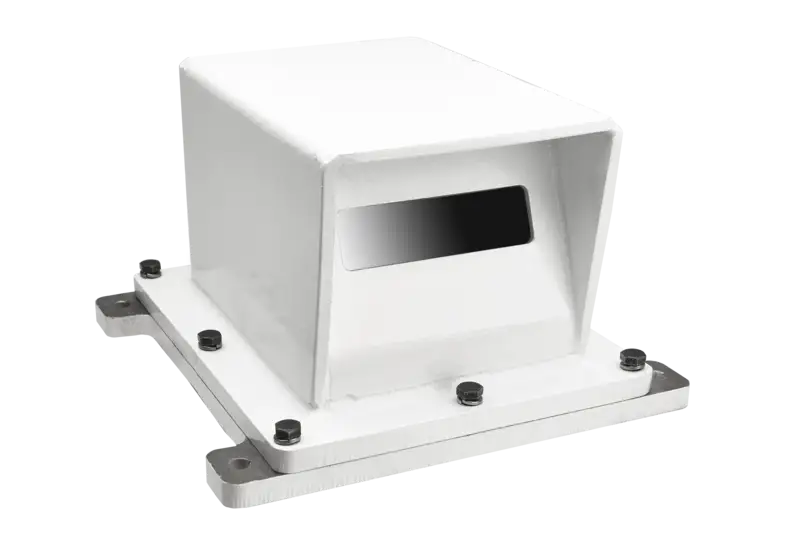

- Explosion Proof (FLP) enclosure

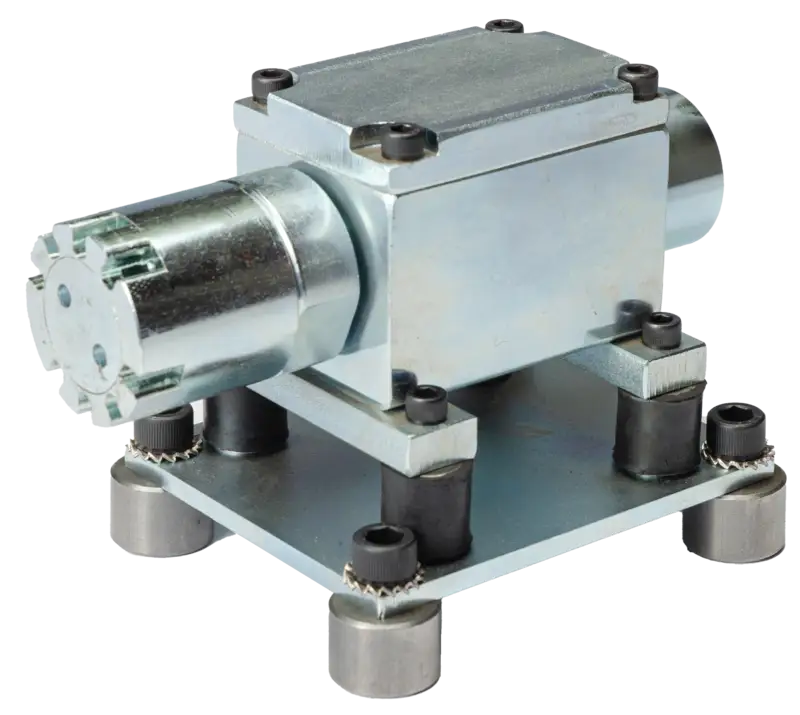

- Laser scanner and controller

- Power Supply Unit

SPECIFICATIONS:

- System supply voltage range: 80 – 264VAC

- Frequency range: 47 – 63Hz

- Laser system supply voltage: 24V DC

- Solenoid supply voltage: 24V DC

- System current consumption: ≤400mA

- Operating temperature: -10ºC to 50ºC

- Laser protection class: Laser class 1M

CERTIFICATION:

- Ex db I Mb

- MASC M/15-1413X (Monitech Type 7 FLP Enclosure)

PRIMARY COMPONENTS