Water Control and Optimisation Systems

Actuating Ball Valve:

FUNCTIONALITY & PERFORMANCE:

- Monitech Actuator Ball Valve (ABV) are part of an self-contained, intelligent water management system for dust suppression spray systems that can be retrofitted to a range of applications where water is used.

- Automatic activation of the actuating ball valves (on/off) eliminates the need to mechanically open and shut the water supply.

- The ABVs are available in both single and dual configurations, also as FLP compliant for either in-bye and out-bye underground or surface applications

- Unlike current “load on belt” wheel driven systems that require frictional contact, Monitech ABVs are an intelligent system that is triggered electrically.

- The system only requires AC supply and an open contact to operate the system. In the event of a power failure a battery backup will shut off the water supply. Manual override if required.

- Typical Applications include:

- Feeder breakers

- Belt Transfer points,

- Belts – supplying water sprays on bottom belts where fine dust has accumulated.

- Bunkers

- Surface belts

- Stockpiles

- ABVs form part of a modulated water management system that can be designed to meet operational demands and/or budgetary constraints.

- Flexibility on installations and trouble-free servicing to avoid unnecessary downtime and improving productivity

- The system includes a cost-effective maintenance kit to keep the system operating without the need to replace.

- Proven and reliable technology

- Ease of Operation

- Robust Design

Specifications:

- Relative humidity: <95% non-condensing

- Operating temperature: -10°C to +50°C

- Input Voltage: 90 – 250VAC

- Pressure Rating: 50Bar

Certification:

- Certified Ex db I Mb

- Certified by MASC in accordance with SANS 60079-1: 2015

- IA Certification Number: MASC M/22 – 2184X

COAL/BLOCKED CHUTE DETECTION SENSOR:

FUNCTIONALITY & PERFORMANCE:

- Monitech Coal and Blocked Chute Detection Sensor is an intelligent autonomous product designed with multiple configurations to assist in the detection of coal on belts and blockages to coal chutes.

- One output is utlised for coal detection and the other for coal blockages. Both detection outputs are wired through separate timer relays, with their own settings.

- The Coal/Blocked Chute detection system is available in an Intrinsically Safe and non-Intrinsically safe versions.

- The sensor can be used as a standalone unit at transfer points but requires a separate PSU to be installed.

- The Coal/Blocked Chute detection sensor has 2 programmable fields:

Coal Detection - The sensor is positioned and programmed above the coal belt where the minimum amount of coal to activate the sensor is set.

- Once coal passes by the sensor a detection field is interrupted, and a signal is sent out to activate the Intelligent Water Management System and/or the Dust Stop Suppression system

- The system shuts off all water once the coal is no longer detected.

Blocked Chute detection: - With the sensor already strategically positioned, the level/height of the maximum allowable pile up of coal is measured from the sensor.

- The blocked chute detection range is then programmed to that measurement.

- Once coal build up exceeds the maximum allowable height, the detection field is interrupted, and a signal is sent out to stop the halt the belt.

- The stop command will stay active for as long as the pile up of coal is detected.

- Proven and reliable technology

- Ease of Operation

- Robust Design

Specifications:

- Relative humidity: <95% non-condensing

- Operating temperature: -10°C to +50°C

- Input Voltage: 24Vdc

Certification:

- Ex rating: Ex ia I

- IA No: MASC M/14-0670X

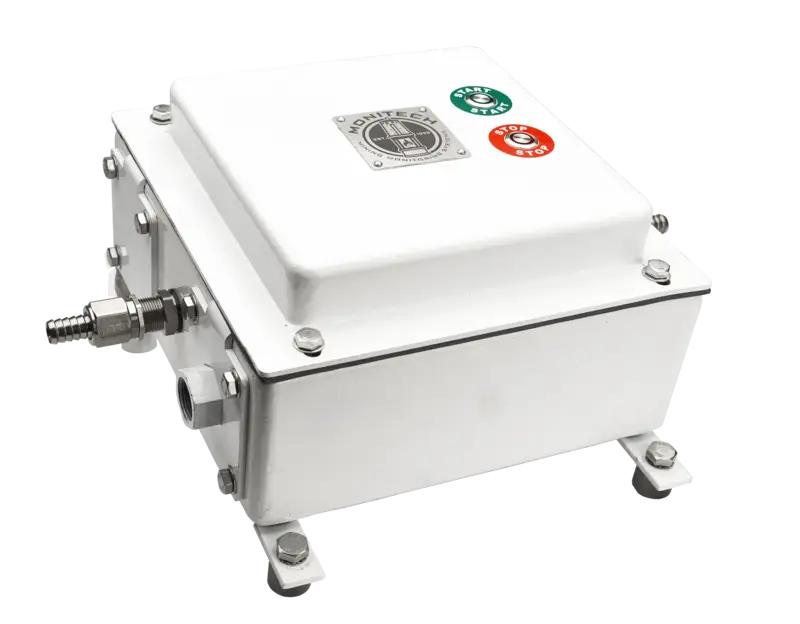

INTELLIGENT WATER FILLING STATION:

FUNCTIONALITY & PERFORMANCE:

- The Monitech Intelligent Water Filling Station is a cost effective water management system for water refilling points in both underground and surface working environments.

- To assist with ongoing challenges in reducing water wastage and avoidable underground section flooding caused by open water systems, this intelligent Water Filling Station offers a reliable autonomous water refilling point.

- The Filling Station is activated by means of a Green Start button on the enclosure.

- The Filling Station remains open for a preset time period (mine specific) and will automatically close once the time lapses.

- If the time lapses before the equipment’s tank is fully filled up, the Green Start button can be pressed again.

- If the Filling process is complete before the time lapses, the Red Stop button will close off the water supply.

- Typically, the Filling Station is fitted nearby a belt drive, a mounting Frame is available

- The Intelligent Water Filling station is a stand-alone system that only requires a 24Vdc supply.

- The Water Filling Unit is fitted with a battery backup that closes the water supply during a power outage.

- Communications systems to surface are available.

- Installations are backed by the Monitech 24/7/365 service offering if required.

- Strong robust design.

Application Points:

- Surface and Underground – In Bye and Out Bye Application points

- Belt Drives

- Water refilling points

Specifications:

- Max. relative humidity: <95% non-condensing

- Operating temperature: -10°C to +50°C

- Input Voltage: 24Vdc

- Pressure Rating: 50Bar

Water Solenoid:

FUNCTIONALITY & PERFORMANCE:

- Monitech solenoids are an intelligent water management system for dust suppression spray systems that can be retrofitted to a range of applications where water is used.

- Automatic activation of Solenoid systems (on/off) eliminates the need to mechanically open and shut the water supply.

- The Solenoids are available in both single and dual configurations, also as I.S and Non-I.S compliant for either in-bye and out-bye underground or surface applications

- Unlike current “load on belt” wheel driven systems that require frictional contact, Monitech solenoids are an intelligent system that is triggered electrically.

- Typical Applications include:

- Feeder breakers

- Belt Transfer points,

- Belts – supplying water sprays on bottom belts where fine dust has accumulated.

- Bunkers

- Surface belts

- Stockpiles

- Solenoids form part of a modulated water management system that can be designed to meet operational demands and/or budgetary constraints.

- Flexibility on installations and trouble-free servicing to avoid unnecessary downtime and improving productivity

- The system includes a cost-effective maintenance kit to keep the system operating without the need to replace.

- Proven technology

- Ease of Operation.

Specifications:

- Temperature rating -40º – 100ºC

- Monitech IS power supply provides 12VDC IS or non-IS

- Solenoid enclosure box.

- Pressure regulator & Gauge certification

Certification:

- Intrinsically Safe Ex ia.

- Ex ia I Ma

- MASC M/19-0152X